These represented the later years of the stationary steam engine and the beginnings of the high speed steam engine the internal combustion oil engine and electrical generating equipment.

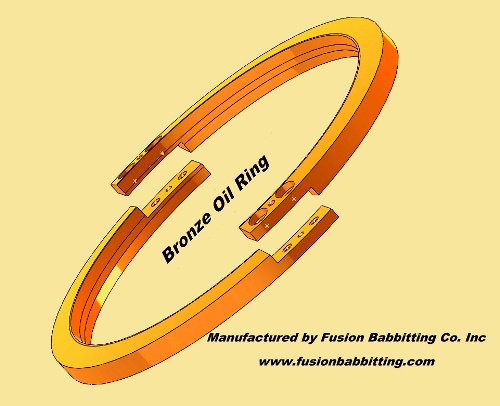

Oil slinger ring design.

A ring oiler or oil ring is a form of oil lubrication system for bearings.

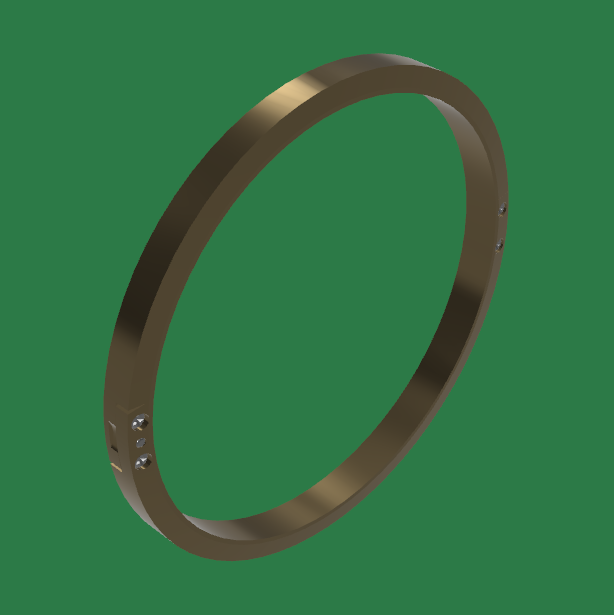

The disc outer edge is immersed some depth into the oil.

Api standard 610 2 10 under lubrication recommends the level to be from 12 to 25 inches from the lower edge of the flinger or above the lower edge of the bore of the oil ring.

However pumps incorporating a two inch shaft operating at 3 600 rpm dn 7 200 would use oil rings sometimes called slinger rings to lift or spray the oil from a sump with its level maintained below the bearing.

Less frictional heat results from lower oil levels figure 2 than from an oil level reaching the center of the bearing.

About two decades later in 1999 at least one major pump manufacturer saw fit to examine the situation more closely.

A disc is mounted inside the bearing housing and is driven by the pump shaft.

In a comprehensive paper the manufacturer described remedial actions which included grade 46 oil viscosity and oil rings made of high performance polymers bradshaw 2000.

There is no reservoir of oil in the housing and oil rings are not used.

Ring oilers were used for medium speed applications with moderate loads during the first half of the 20th century.

Purge mist lubrication utilizes the same principles of pure mist but a reservoir of oil in the housing exists.

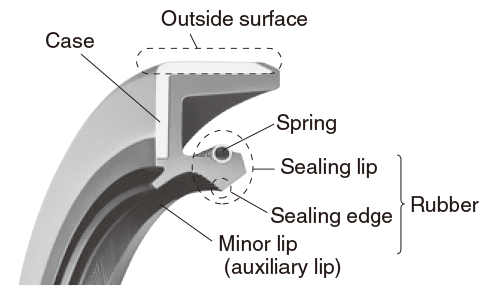

The design of the bearing is vital for ensuring an effective process.

Ensuring that the oil ring flinger is immersed at the correct oil level is crucial.

Pumps using oil rings can suffer the following lubrication problems.

As it rotates oil is lifted from the sump and thrown onto the inside of the housing.

When you choose wheeler expect world class 5 axis cnc manufacturing precision rebabbitting services creating the best babbit bearings and innovative design modeling assistance.

An oil ring collar or a wick is typically used for supplying the oil to the bearing through the use of a pressurized system.

Our 17 000 square foot manufacturing site houses an in house foundry cutting edge technology 40 000 drawings and we can offer access to the largest inventory of.

Oil slinger design considerations and prior art the oil slinger disc arrangement is simple to understand.

Instead of greasing the part a high speed journal bearing design relies on oil lubrication.